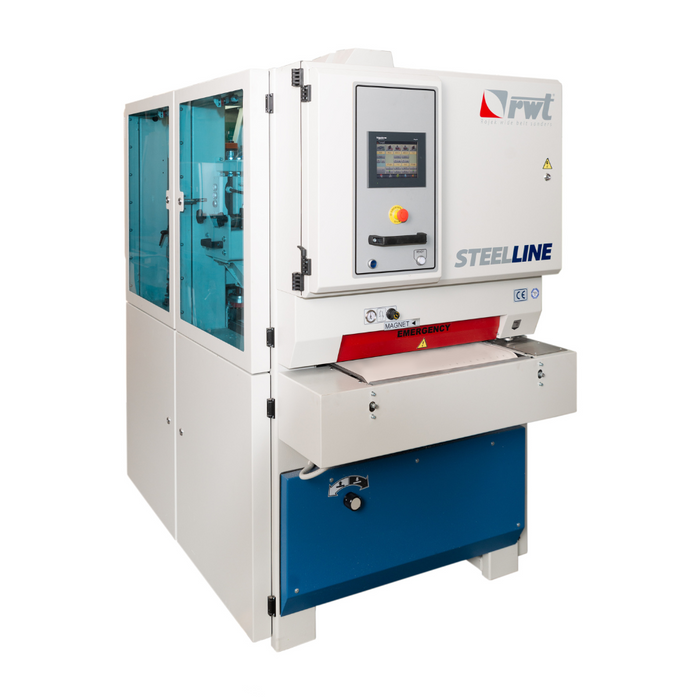

RWT STEELINE BSM 650 EDGE-ROUNDING & DEBURRING MACHINE

The BSM 650 is a deburring and edge rounding machine designed to clean up burrs and create smooth edges on metal parts cut by laser, shearing, or punching. Its ability to process parts up to 650mm in width, combined with its capability to handle even the smallest parts measuring 50x50mm, make it a practical option for a wide range of applications. The small footprint provides the benefit of being space-efficient and easy to integrate into smaller workspaces.

With precise adjustment wheels, buttons, and speed inverters, the BSM 650 is easy to operate, allowing you to control every stage of the deburring process with ease. It is equipped to handle a variety of materials including stainless steel, steel, and aluminum, making it a reliable and versatile solution.

The Machines BSM series can be equipped with the following operating units:

- Grinding unit with the grinding belt (R) - removes burrs protruding above the surface of the material, removes scales and corrosion from the surface

- Planetary disc brush unit (D) - rounds the edges, creating radius and removing oxide layer on the sides after laser cutting.

- Gyroscopic unit (A) with lamela brushes – deburring and edgerounding without foil removing, surface unification.

- Brushing unit of grinding fleece (B) - cleans and prepolishes surface material

Main advantages of the machine:

- Modular system - we design the machine precisely according to your needs

- High quality and uniform deburring all the edges of the product

- Processing very small workpieces using the magnetic or the vacuum table

- Very easy operating the machine by touchscreen Schneider Electric

- Grinding, deburring and finishing with one machine

- Very quick change of the tools and the rigid machine frame